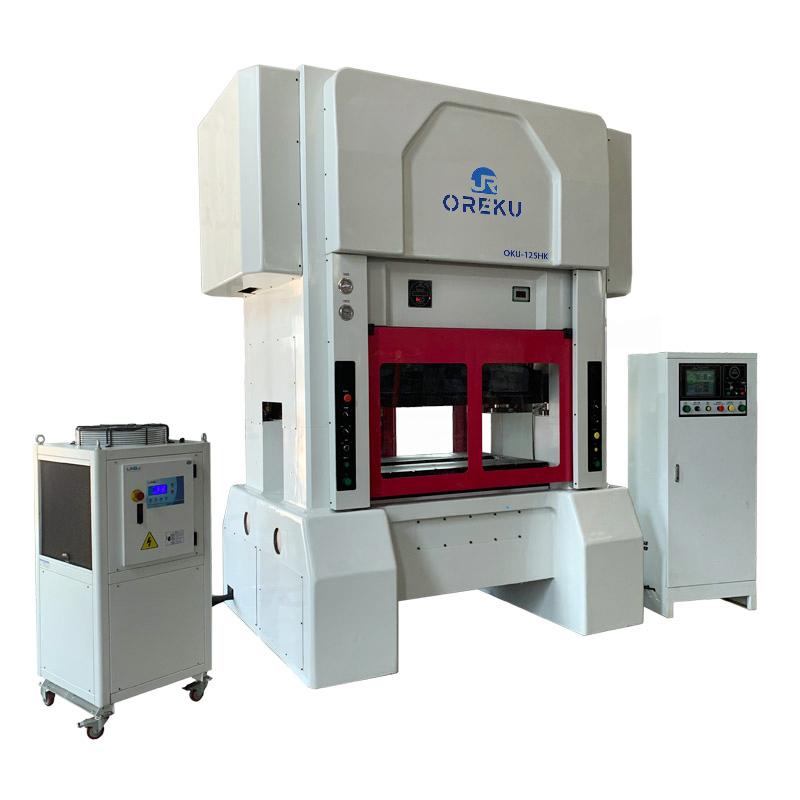

OREKU 60HK High Speed mechanical power punching press machine

Model No.︰OKU-60HK

Brand Name︰OREKU

Country of Origin︰China

Unit Price︰CNY ¥ 80000 / pcs

Minimum Order︰1 pcs

Product Description

OREKU 60HK High Speed mechanical power punching press machine

Model: OREKU-65T

Brand:OREKU C-type punching machine

Precision: JIS special grade

Speed: 700 times/min

Tonnage: 65 tons

Stroke: 30mm

Price: Negotiable.

C type 65 tons high speed punch press accessories:

1. Die height display

2. inch movement function

Single-action function

Linkage function

3. Vertex stop function

4. Emergency stop function

5. Maximum/minimum speed limit function

6. Abnormal air pressure function

7. Lubrication oil pressure abnormal function

8. Hydraulic mold clamping

9. Dynamic balance

10. Accumulation counting function

11. A set of batch control

12. Punching machine without material automatic stopping device

13.Lubricating oil circulation function

14. Air cushion feet

15.Tool box

16.Working light

C type 65 tons high speed punching machine optional accessories:

1.Roller feeder (width option: 105/138mm)

2. Clamp feeder (single/double)

3. Gear feeder (width options: 150/200/300/400)

4.Electronic disk (load capacity 500kg)

5.Single side double hand rewinding machine

6.Single point lower dead center monitor

7.Double-point lower dead center monitor

8.Electric mold adjustment function

C type 65 tons high-speed punching machine parameters:

Nominal force: 65T

Stroke: 30/40/50

Stroke number: 200-700/200-600/200-500 S.P.M.

Closed height: 215-265/210-260/205-255 mm

Table area: 890×580mm

Slider area:600×400mm

Adjustment volume: 50mm

Discharge hole:150×450(550)mm

Motor: 15HP

Total weight:9.2 tons

Circulation system: forced lubrication + oil coolant

Transmission system: Inverter

Clutch & Brake: Air&Friction

Stopping point: Standard

Shock absorbing system: Optional

C type 65 tons high speed punch press structure

C-type 65-ton high-speed punching machine stamping products

C-type 65-ton high-speed punch press maintenance:

1, often keep the center column, the slider guide column clean, as well as racking the mold to keep the mold base plate free of dirt to ensure the cleanliness of the platform to avoid scratches. 2, the new machine in the use of 1 month, the flywheel at the addition of grease (including feeder), if not refueled for a long time, will lead to internal wear of the flywheel, affecting the performance of the machine tool, and each subsequent maintenance needs to be added (high temperature 150 ℃ more than the grease)

3, the replacement of machine circulating oil: new machine in 1 month to replace 1 time, and then every six months to replace 1 time, to ensure the normal operation of the machine and precision (32 # mechanical oil or Mobil 1405 #)

C-type 65-ton high-speed punching machine use method:

1, before starting the machine, you should set the speed potentiometer (W) set on the control panel to the lowest point (O point) position.

2、After the main power switch (DK) is turned on, the power indicator light is on, and the phase sequence indicator light should also be on, otherwise the phase sequence should be checked to see if it is correct.

3、Break the phase after turning on the control circuit with the key switch. Indicator lamp three should be bright at the same time, otherwise should check, troubleshooting.

4, clockwise adjustment of the "speed" potentiometer, the main motor drive flywheel start, the speed should be smooth without vibration, no impact and other phenomena exist.

5, in the process of connecting the main clutch, should be operated at the same time left and right hand. In the process of formal stamping, the external control key switch should be turned on and the key switch of the regulator should be in the state of reset before it can work formally, otherwise the feeding switch and the mold failure signal will be out of control.

6、During the formal stamping process, since the static differential rate of the main motor varies with different loads, when stamping different parts, the electromagnetic register set on the control board can be used to correct the rotational speed.

The following are some common types of high-speed punch press products:

Gantry high-speed punch press: with a larger table and higher stamping capacity, it is suitable for the stamping of large parts;

C-type high-speed punch press: more compact structure, suitable for stamping small and medium-sized parts;

Single-point high-speed press: usually with higher stamping speed and precision;

Closed-type high-speed press: with better rigidity and stability, suitable for high-precision stamping processing.

Payment Terms︰ TT / LC / DP / DA

Product Image